Stéphanie Barrault, head of the Circular Design Experience project: applying all of the circular-economy principles to the construction sector

4 minutes of reading

In France, the construction sector generates more than 40 million tonnes of waste every year and consumes large quantities of resources to meet the needs of renovation and new construction. A situation that contributes to threatening certain resources with scarcity, or even shortage, in the medium to long term. For example, this is the case with sand, of which the sector is a large consumer.

A situation that contributes to threatening certain resources with scarcity, or even shortage, in the medium to long term. For example, this is the case with sand, of which the sector is a large consumer.

Taking into account the “finiteness” of the Earth and the limited nature of certain resources means reconsidering our practices and developing our models. In particular, by moving towards a circular economic model, which limits wastage of resources and reduces the environmental impact linked to the economic exchange and production system.

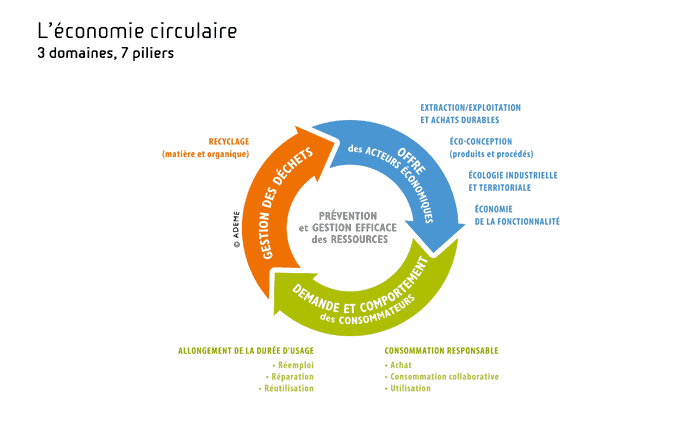

However, switching to a circular economic model involves taking action on all of the pillars: eco-design of buildings in order to limit future water and energy consumption, reducing consumption of raw materials, sourcing supplies locally, managing the environmental impacts of construction sites, recycling products at the end of their use or their life, optimising the usage intensity of the building, anticipating the potential for reusing materials at the point of renovation or deconstruction, etc.

This is the project’s ambition: to explore all the available levers in order to inject the principles of circularity into our projects.

However, switching to a circular economic model involves taking action on all of the pillars: eco-design of buildings in order to limit future water and energy consumption, reducing consumption of raw materials, sourcing supplies locally, managing the environmental impacts of construction sites, recycling products at the end of their use or their life, optimising the usage intensity of the building, anticipating the potential for reusing materials at the point of renovation or deconstruction, etc.

This is the project’s ambition: to explore all the available levers in order to inject the principles of circularity into our projects.

In this context, Bouygues Construction conducted the R&D project entitled “Circular Design Experience”. What does it involve and what is its goal?

Stéphanie Barrault, head of the Circular Design Experience project: applying all of the circular-economy principles to the construction sector Stéphanie Barrault, head of the Circular Design Experience project: applying all of the circular-economy principles to the construction sector The Circular Design Experience project aims to explore the potential for the application of all of the principles of the circular economy to the construction sector, with a view to reducing as much as possible the use of non-renewable resources in construction and renovation projects. ADEME (the French Environment and Energy Management Agency) has defined seven pillars of the circular economy, on which there is currently consensus between the key players. However, the circular-economy approach is still too often limited to the issues of resources and waste. For example, current certifications for the construction sector focus primarily on the responsible consumption of resources, and recycling. However, switching to a circular economic model involves taking action on all of the pillars: eco-design of buildings in order to limit future water and energy consumption, reducing consumption of raw materials, sourcing supplies locally, managing the environmental impacts of construction sites, recycling products at the end of their use or their life, optimising the usage intensity of the building, anticipating the potential for reusing materials at the point of renovation or deconstruction, etc.

This is the project’s ambition: to explore all the available levers in order to inject the principles of circularity into our projects.

However, switching to a circular economic model involves taking action on all of the pillars: eco-design of buildings in order to limit future water and energy consumption, reducing consumption of raw materials, sourcing supplies locally, managing the environmental impacts of construction sites, recycling products at the end of their use or their life, optimising the usage intensity of the building, anticipating the potential for reusing materials at the point of renovation or deconstruction, etc.

This is the project’s ambition: to explore all the available levers in order to inject the principles of circularity into our projects.

How did the project progress and what tools have been put in place?

Launched in May 2019, the programme has been deployed for 6 months in the form of five working groups which have mobilised some forty experts. Two of them were focusing on the technological aspects: what are the alternative structures to concrete (low-carbon concrete, self-healing concrete, clay, façades in load-bearing straw bales, etc.) and what is the re-use potential for interior-finish materials (paint, internal joinery, etc.)? Two others explored the design aspect: how to integrate the programmatic constraints associated with the circularity of buildings, and what are the potential uses of buildings for more environmentally and socially responsible operation? Finally, a cross-functional workshop was dedicated to calculating multi-criteria performance in order to define a performance evaluation system that addresses the challenges of the circular economy. The objective was to provide all Bouygues Construction teams working in construction with decision-support tools and the keys to introduce circular-economy solutions into their projects: a “circular economy” support guide for the design teams, an indicator grid and tools for assessing the multi-criteria performance of products and buildings, a catalogue of interior-finish materials with potential for re-use, with usage recommendations and evaluations of their potential for “circularity”, etc.What principles guided the approach? In particular, what did you envisage to encourage the operational appropriation of the tools?

The working groups were formed on a voluntary basis. Alongside expert contacts on the topics discussed, volunteer employees were able to join the programme. A way of integrating field concerns from the start, and ensuring the practical suitability of the tools. We also tried to integrate ourselves as much as possible into existing operational practices in order to encourage ownership of tools and their use in projects. We always remained aware that the tools had to support the development process of a project. On the programming aspect, for example, we worked on the basis of existing tools, and injected into them the principles and issues related to the circular economy. In the diagnosis phase, we are thus integrating a methodology to comprehensively identify the circular-economy challenges of the region and the site studied: the local economic system, the region’s capacity for food self-sufficiency, and the urban metabolism are some of the dimensions that will be analysed. Another aspect dealt with in depth is that the functional programme seeks to reduce the consumption of resources from upstream, by exploring, for example, the building’s capacities for hybridisation: promoting daily flexibility in order to increase the use of buildings and reduce construction needs, allow long-term reversibility of use, etc.What are the outlooks and next steps?

An initial test was carried out in 2019 on the urban project at La Maillerie, a site of 10.5 hectares located in the centre of the Lille conurbation on a former 3 Suisses logistics site. From now on, the aim is to support a project to implement the principles and tools that were the result of this approach. In 2020, the objective will also be to add to the approach by exploring other dimensions: studying the potential for resilience and durability of the technical installations, and envisaging the possibilities for disassembly, re-use and integration of biosourced materials for the building envelope. Finally, synergies will need to be found with other R&D programmes conducted at Bouygues Construction in order to make the tools consistent. Several R&D programmes are converging, such as the Low-Carbon Concept Building, which is looking at a building model that emits as little CO2 as possible.Most read

More reading

Read also

Article

20 minutes of reading

Energy

in partnership with

‘Paris at 50°C’: a fact-finding mission to prepare Paris for future heatwaves

Article

2 minutes of reading

What if your sites were supplied via rivers instead of roads?

Article

3 minutes of reading