Objective: zero waste…

3 minutes of reading

Regulatory pressure is growing on how building and public works waste is processed. The sector produces 70% of waste in France (245 million tonnes, 46 million tonnes of which from the construction sector).

Construction sites generate multiple different types of waste. There is inert waste, most of which comes from public works or demolition. Its recovery rate can be viewed as acceptable, although it is often undercycled, i.e. recycled with a deterioration in quality. An example of this is using aggregate from technical concrete to make road backfill. There is also non-hazardous (non-inert) waste, for which there is a struggle to achieve a (material and energy) recovery rate of 50% on average.

European regulations, as described in the Law on energy transition for green growth, set an objective of 70% of material recovery for the construction sector by 2020.

Furthermore, as a positive sign that the climate emergency is being increasingly taken into consideration, the environmental requirements on project owners are also becoming ever-increasingly strict.

To achieve this objective, a pragmatic campaign was launched in 2019: testing out Zero Final Waste Construction Sites. This test project was implemented in every operational unit in France. This campaign, which forms a logical continuation to the work on the circular economy carried out internally, will allow each operational unit to take ownership, gradually, of the most suitable levers for reducing the environmental impact of our construction activities.

Two work streams must be envisaged in order to aim for 0 waste:

#1 – Upstream of production, when the building is designed: reduce loss of materials and packaging to the greatest extent possible.

Examples include custom layouts* for plaster partition walls and packaging in bulk. These two already tried and tested initiatives are inspired by industrialisation.

#2 – Downstream, with waste sorting at the source.

Sorting by separation, which is the logical solution for waste like metals, could also be applied to other flows of waste under acceptable technical and economic conditions.

This virtuous cycle, launched in Ile de France with the “hacktivators” project or in other regions such as in the Bouygues Bâtiment Nord Est project for Maubeuge Hospital, will be extended to all selected test construction sites by the end of 2019.

The first feedback from 0 waste construction site teams is expected in November; watch this space… !

* Custom layouts are a custom design method that involve drawing and preparing the exact number and width of material cuts in advance, in order to reduce waste associated with cutting materials to size on site.

To achieve this objective, a pragmatic campaign was launched in 2019: testing out Zero Final Waste Construction Sites. This test project was implemented in every operational unit in France. This campaign, which forms a logical continuation to the work on the circular economy carried out internally, will allow each operational unit to take ownership, gradually, of the most suitable levers for reducing the environmental impact of our construction activities.

Two work streams must be envisaged in order to aim for 0 waste:

#1 – Upstream of production, when the building is designed: reduce loss of materials and packaging to the greatest extent possible.

Examples include custom layouts* for plaster partition walls and packaging in bulk. These two already tried and tested initiatives are inspired by industrialisation.

#2 – Downstream, with waste sorting at the source.

Sorting by separation, which is the logical solution for waste like metals, could also be applied to other flows of waste under acceptable technical and economic conditions.

This virtuous cycle, launched in Ile de France with the “hacktivators” project or in other regions such as in the Bouygues Bâtiment Nord Est project for Maubeuge Hospital, will be extended to all selected test construction sites by the end of 2019.

The first feedback from 0 waste construction site teams is expected in November; watch this space… !

* Custom layouts are a custom design method that involve drawing and preparing the exact number and width of material cuts in advance, in order to reduce waste associated with cutting materials to size on site.

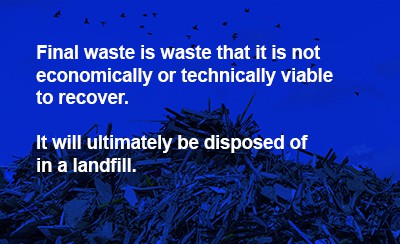

Against this background, Bouygues Bâtiment France Europe’s ambition is to strive for zero final waste.

To achieve this objective, a pragmatic campaign was launched in 2019: testing out Zero Final Waste Construction Sites. This test project was implemented in every operational unit in France. This campaign, which forms a logical continuation to the work on the circular economy carried out internally, will allow each operational unit to take ownership, gradually, of the most suitable levers for reducing the environmental impact of our construction activities.

Two work streams must be envisaged in order to aim for 0 waste:

#1 – Upstream of production, when the building is designed: reduce loss of materials and packaging to the greatest extent possible.

Examples include custom layouts* for plaster partition walls and packaging in bulk. These two already tried and tested initiatives are inspired by industrialisation.

#2 – Downstream, with waste sorting at the source.

Sorting by separation, which is the logical solution for waste like metals, could also be applied to other flows of waste under acceptable technical and economic conditions.

This virtuous cycle, launched in Ile de France with the “hacktivators” project or in other regions such as in the Bouygues Bâtiment Nord Est project for Maubeuge Hospital, will be extended to all selected test construction sites by the end of 2019.

The first feedback from 0 waste construction site teams is expected in November; watch this space… !

* Custom layouts are a custom design method that involve drawing and preparing the exact number and width of material cuts in advance, in order to reduce waste associated with cutting materials to size on site.

To achieve this objective, a pragmatic campaign was launched in 2019: testing out Zero Final Waste Construction Sites. This test project was implemented in every operational unit in France. This campaign, which forms a logical continuation to the work on the circular economy carried out internally, will allow each operational unit to take ownership, gradually, of the most suitable levers for reducing the environmental impact of our construction activities.

Two work streams must be envisaged in order to aim for 0 waste:

#1 – Upstream of production, when the building is designed: reduce loss of materials and packaging to the greatest extent possible.

Examples include custom layouts* for plaster partition walls and packaging in bulk. These two already tried and tested initiatives are inspired by industrialisation.

#2 – Downstream, with waste sorting at the source.

Sorting by separation, which is the logical solution for waste like metals, could also be applied to other flows of waste under acceptable technical and economic conditions.

This virtuous cycle, launched in Ile de France with the “hacktivators” project or in other regions such as in the Bouygues Bâtiment Nord Est project for Maubeuge Hospital, will be extended to all selected test construction sites by the end of 2019.

The first feedback from 0 waste construction site teams is expected in November; watch this space… !

* Custom layouts are a custom design method that involve drawing and preparing the exact number and width of material cuts in advance, in order to reduce waste associated with cutting materials to size on site. More reading

Read also

What lies ahead? 7 megatrends and their influence on construction, real estate and urban development

Article

20 minutes of reading