Is digitalisation the key to building differently

5 minutes of reading

Attracting talent, mitigating climate change, and improving productivity: These are the construction sector’s three main challenges. BIM and various digital tools offer useful solutions, but these are not enough.

So, what place does digitalisation have in the future of construction, and what added value does it offer?

“Digitalisation is an instrument,” says Frédéric Gal, manager of Bouygues Construction’s business modernisation project and digital project management platform (PMNP). “We know perfectly well what it will allow us to do: automate, go faster, accelerate our manner of building. BIM was the first pillar of digitalisation, marking the dawn of this new era for construction. We now have to find the right tools to speed up its growth so that we can overcome the challenges that face the construction sector. ” For good reason, since ecologically, everyone involved in construction knows “there is an urgent need to change the way we build. Similarly, productivity in our sector has seen little change overall. As for the image of the industry, it has deteriorated-, which does not encourage young workers to enter our professions. ”

The end of a way of building?

Fortunately, not everything in past and present construction models has to be thrown away However, according to Frederic Gal, it’s clear that the conventional manner of building needs to be revolutionised. What is this all about? The challenge is to industrialise new methods in such a way as to improve the productivity and profitability of future constructions while considerably reducing their carbon impact. In practice, that means “a building should no longer be thought of as a sum of lots with appointed professionals (mason, plumber, electrician, painter, etc.); instead, we should split the process of building into modules or sub-modules (technical shaft, landing shaft, staircase, floor, wall, etc.). Parts and sub-parts that would all be specialisations. ” There is a two-fold benefit to this: “it reduces the number of interfaces and increases productivity. ”Improving productivity by facilitating collaborative work

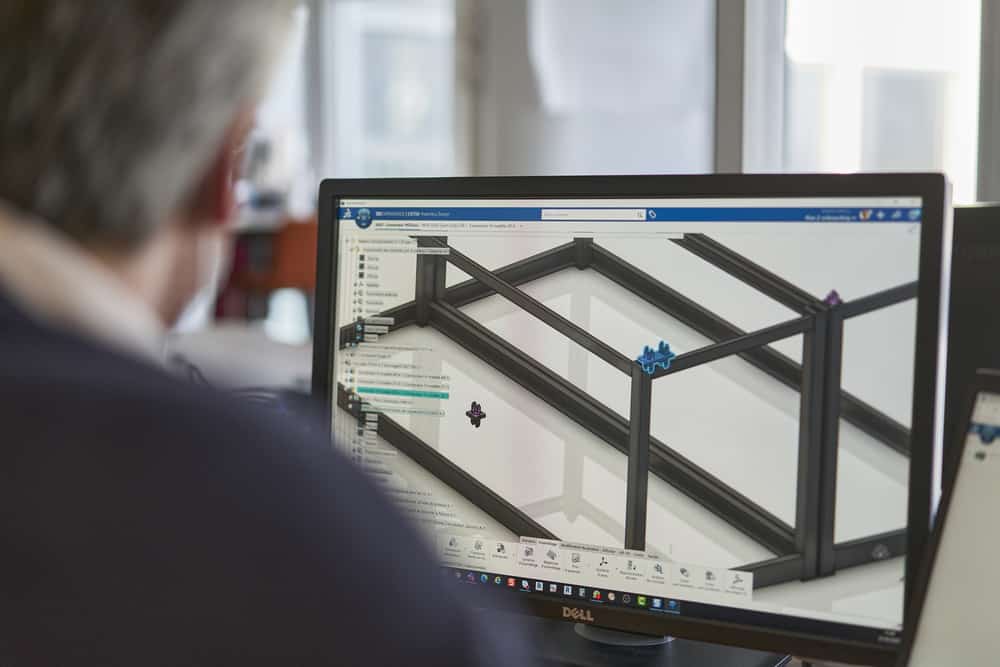

To make the most of digitalisation’s potential to benefit construction, it is essential to identify the right digital tools. Those that enable us to move towards a more resilient and sustainable construction model, one that is faster and more economical. In view of this, Bouygues Construction has entered into a partnership with Dassault Système, -world leader in software for industry. “We looked into the relevance of using their tools in the construction sector,” recalls Bouygues Construction’s project manager for the modernisation of trades and the PMNP platform. “We assessed their impacts and benefits, as well the difficulties involved in their implementation. This analysis revealed that some of the tools were truly well-suited to the task of shifting the construction sector’s methods in order to meet its challenges. The first tool is CATIA, a configurable drawing software in which we can do generative design to play out thousands of scenarios… It’s very practical: all we have to do is explain to the tool how to draw, and it then draws for us. We also use the 3D experience platform, a collaborative tool that allows you to share 3D models, assign a task to someone, and follow the project schedule. In short, everyone involved in the project can work on it, make comments that can be seen by everyone else, assign a task to someone, create validation flows, and so on. Such collaborative work is a real time saver and, again, improves productivity. ” So, no more site meetings with post-its and chalkboards! Thanks to digitalisation, everyone involved in a project can now interact simultaneously, remotely, and at any time on the 3D model of a project or, more simply, on a lean board. This works by sharing the right, useful information with one another so that each can move forward at their own level.Decarbonising construction while improving its profitability

Another advantage of digitalisation is that, since it can encompass the most minute details (at the scale of a screw), it increases the accuracy of estimates for a construction project’s purchasing requirements. Consequently, future construction waste is reduced to the bare minimum, as is the waste of raw materials. This is one of the keys to reducing the carbon impact of construction, while also being an asset in terms of profitability. Logistically, digitalisation makes it possible to order any constructive element to the right size by favouring pre-cutting in the factory. The result is, again, very positive for the environment: less waste and genuine optimisation of the use of materials. “With the high level of informational detail enabled by certain digital tools, automatic calculations, and instant messaging systems, a single board cut intelligently in the factory may suffice. Before, even where little material was needed, the process might still use up two boards; so a part would automatically go to waste. There’s recycling, of course, but if we’re to achieve our environmental goals, nothing beats using only what we really need! ”“With today’s digital tools, everything is planned: the number of screws, their performance, the dimensions of each board, etc. Everything is listed! All we need to do is measure everything in advance, place an order, and assemble the different elements upon receipt. Not only is this clearly a guaranteed time-saver, it’s also more economical and ecological! ” Frédéric Gal, manager of the business modernisation project and the digital project management platform (PMNP) at Bouygues Construction

Increasing security for people on site thanks to a very fine level of precision

More precision means less improvisation. And so much the better! “Digitalisation allows you to build before you build,” emphasises Frédéric Gal of Bouygues Construction. Everything’s been planned for ahead of time, which inevitably minimises the risks for the field teams. There’s less and less need for labourers to use portable electrical equipment on site to make cuts or drill. Until now, such work was a source of accidents. Now, everything is prepared and anticipated in advance. That makes it possible to eliminate both the time wasted by the teams and the use of raw materials that ultimately prove unnecessary. The teams can focus on the essentials, optimise their performance, and provide construction sites with their real professional added value, while reducing the risk of accidents. ”Digitalisation and energy renovation: the winning duo for future buildings?

Horizon Europe (formerly Horizon 2020) is an organisation developed by Europe to structure calls for R&D projects. Its mission: to prepare for the future! Every year, several billion euros are thus invested by Europe in R&D projects. The investment spans across many different fields, including agriculture, industry, biotech, medical, construction, and so on: enough to effectively identify the sectors and technologies in which Europe needs to invest in R&D! Unsurprisingly, many of the projects are related to energy renovation. And “Bouygues Construction is involved in several of these projects, since once they leave the laboratories, they need to be tested in a real environment,” explains Christian de Nacquard, Energy Performance R&D Director of Bouygues Bâtiment International. This test phase is crucial as it identifies the adaptation constraints of each innovation to a building! Of course, we also sometimes develop new solutions, and these rely more than ever on digital technology and energy renovation. ” This is evidenced by three of the projects Bouygues Construction is engaged in that are currently helping to digitise energy renovation.Rinno

Horizon 2020 project won two years ago. What’s the concept? A digital platform that brings together all the phases of a project (from the upstream study to the use of the building in operation after renovation). The purpose: to enable all stakeholders to act and communicate on a single platform. “As part of this project, in which other European partners are involved, we have developed a logistics module called E-logistic, along with a site management module called E-cockpit,” says the R&D director of Bouygues Bâtiment International. This project is very similar to Bouygues Construction’s digital platform project (PMNP), and actually feeds its results into the platform to improve it. ” In practice, Rinno aims to speed up and simplify the energy renovation process by modelling the energy aspect of a building; optimising renovation scenarios; optimising work schedules and phasing; providing site monitoring and assistance; and simplifying operations through the industrialisation of technical solutions. It holds great promise for the future!Infinite

An energy renovation project for social housing. The goal of this project is to simplify energy renovation via the industrialisation of facade panels made of insulation, and that of energy systems capable of distributing cold, heat, and ventilation in housing. “Another advantage is that these panels capture heat using integrated solar panels. This comprehensive ensemble has real potential to provide efficient energy renovation for housing while minimising the impact on the users who live there. ” This would boost energy renovation in occupied accommodation. And that’s not all. Digital innovation is taken a step further, since, as part of this project, Bouygues Construction is in the process of developing a prototype predictive thermostat. Drawing real-time information from the analysis of a home’s consumption data and behaviour, this thermostat can predict the energy bill that the occupant will be faced with at the end of the year. “It’s a predictive solution that aims to effectively inform consumers of how their electricity consumption varies as time goes by, rather than just once a year -when they receive the bill. ” This would encourage less energy-intensive actions!Response

A large-scale project that aims to go beyond the simple building! The purpose: to transform an entire district, after energy renovation, into a positive energy district. This is a real challenge for the future that, once again, relies on digital technology. “Digitalisation can enable us to reduce carbon emissions not only in the construction phase, but also in the operation of buildings”, as Christian de Nacquard, R&D Energy Performance Director at Bouygues Bâtiment International, reminds us.More reading

Read also

What lies ahead? 7 megatrends and their influence on construction, real estate and urban development

Article

20 minutes of reading